Product

Products

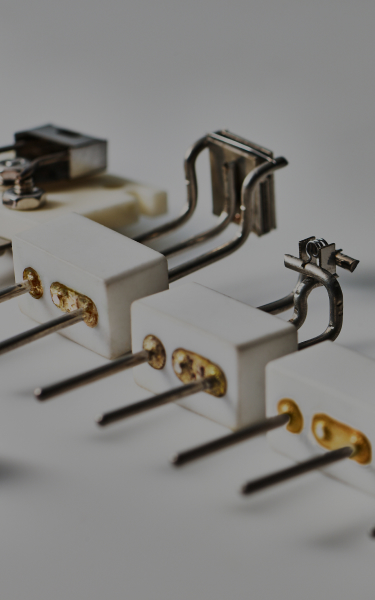

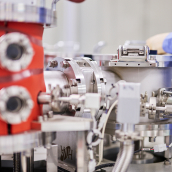

Daiwa provides special materials such as W, Mo, and Ta, and parts for micro-precision and high vacuum applications.

We specialize in the fine machining of rare metal materials such as tungsten, molybdenum, and tantalum, and design, machine, and assemble precision parts used in ultra-high vacuum environments.

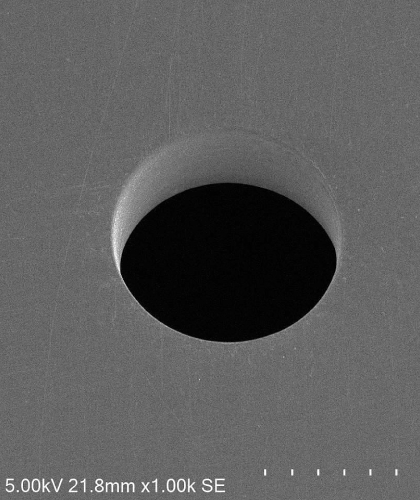

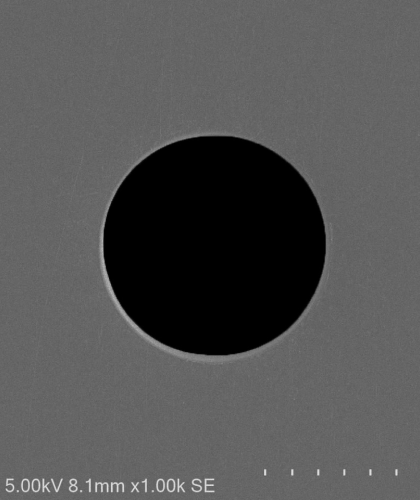

Electron Microscope Parts

There are two main types of electron microscope: scanning electron microscopes (SEM) and transmission electron microscopes (TEM).

Mass Spectrometer, Semiconductor Manufacturing Equipment, and Industrial Machinery Parts

Technology

Technology

Here we introduce the proprietary technology Daiwa has cultivated over half a century.

In addition to in-house machining, we also offer a one-stop shop for a variety of special parts through our network of partners with high expertise in their respective fields.

Introduction to our technology

Micro electrical discharge machining (micro-EDM)

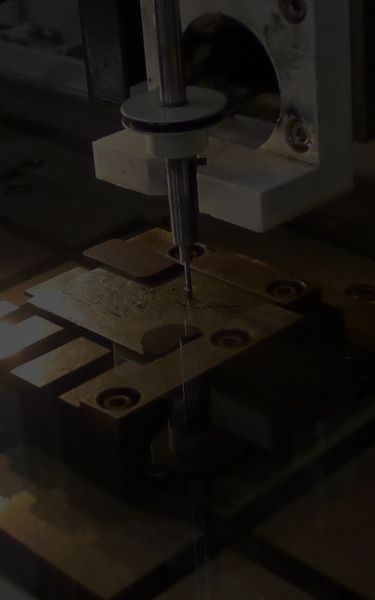

Ultra-fine hole machining is normally difficult, but with our in-house ultra-fine discharge electrodes, it is now possible to perform hole machining w...

Utilizing special deburring technology, we are able to perform mirror surface finishing up to the inner surface of fine holes.

Utilizing special cleaning technology, we are able to remove nano-level contaminants.

We perform osmium deposition by plasma-enhanced chemical vapor deposition (PECVD) to form stable conductive thin film.

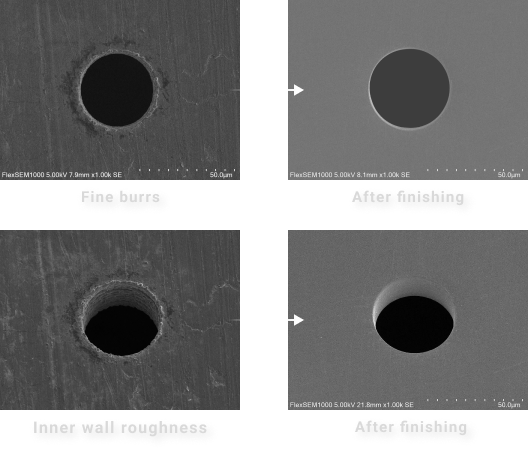

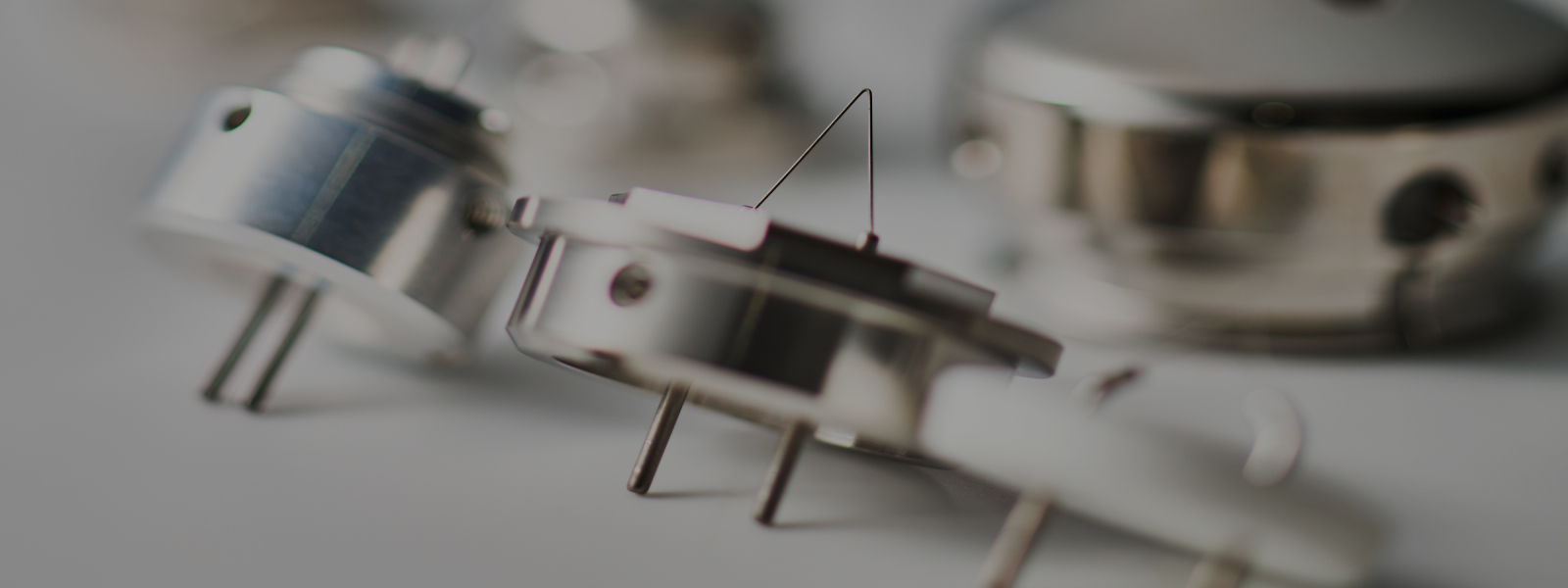

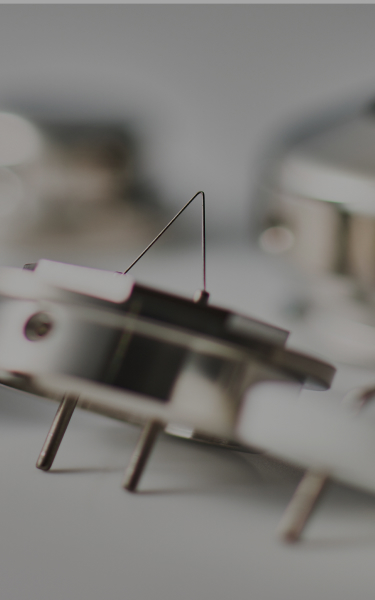

Electron source, X-ray source filament machining

We manufacture parts by leveraging technologies such as the winding of ultra-fine wire coils, tungsten probe polishing, precision assembly by spot wel...

Surface Treatment, Heat Treatment

We respond to customer requests for plating, heat treatment, and film formation after part machining.

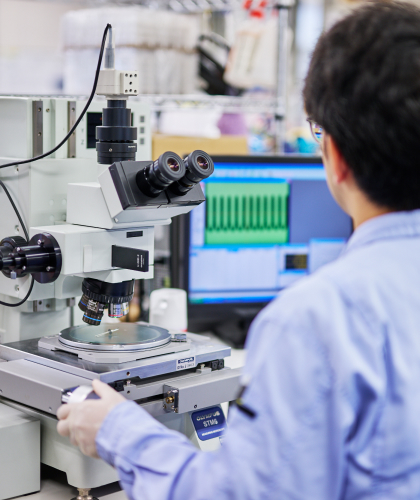

We provide support for all kinds of precision inspection such as optical microscopy, measurement microscopy, and electron microscopy.

Introduction to Other Machining Methods

Through our own technology and cooperation with partner companies, Daiwa supplies finished products with our start-to-finish manufacturing system.

Flow

Transaction Flow

Here we introduce the transaction flow

from inquiry to shipping.

Company

About Us

To meet the needs of many customers

Daiwa was established in 1967 as a manufacturer of filaments for electron microscopes.

以With our focus on various parts for electron microscopes, we have since spent more than half a century providing special functional parts for advanced equipment such as analytical equipment, medical equipment, and semiconductor manufacturing equipment.

We will continue to contribute to the development of science and humanity in any way we can.

Company

About Us

To meet the needs of many customers

Daiwa was established in 1967 as a manufacturer of filaments for electron microscopes.

With our focus on various parts for electron microscopes, we have since spent more than half a century providing special functional parts for advanced equipment such as analytical equipment, medical equipment, and semiconductor manufacturing equipment.

We will continue to contribute to the development of science and humanity in any way we can.