Precision and special cleaning of electron microscope parts

We carry out precision cleaning of aperture plates incorporated into electron microscopes and semiconductor inspection equipment. Even if holes themselves are clean and have no burrs, dirt or marks found by magnifying can be a problem. We are able to remove even small dirt or marks that cannot be detected with a visual check.

Do you have such concerns with

precision cleaning?

- Concern 01

I cannot find a subcontractor to whom I can entrust important vacuum parts.

- Concern 02

I have parts with unacceptable dirt, but we can’t seem to find a company who can handle electron microscope inspections.

- Concern 03

I had precision cleaning carried out, but don’t know if the parts are really clean. I want you to check them thoroughly.

- Concern 04

I want to clean small parts. Are there any companies that can handle this?

Daiwa precision cleaning and special cleaning

Daiwa specializes in apertures for electron microscopes. And because these are vacuum parts, degassing may be necessary, but we handle all of this by conducting a 100% inspection. Parts that have been cleaned and inspected are vacuum-packed and delivered.

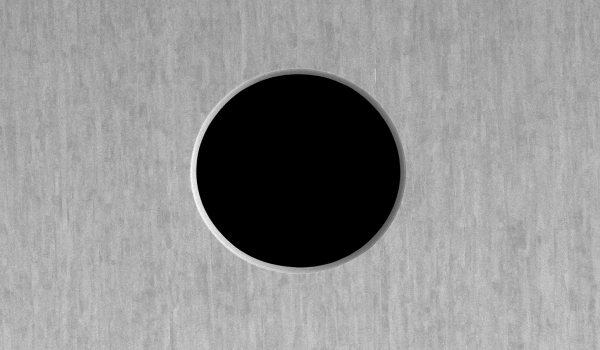

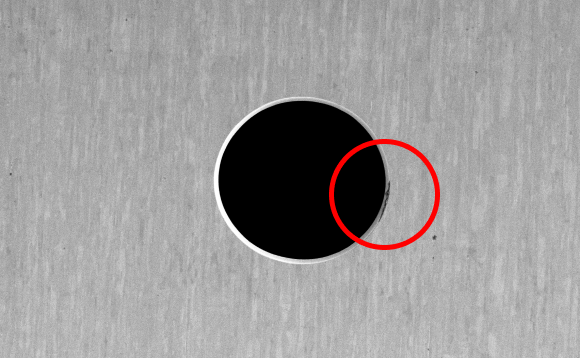

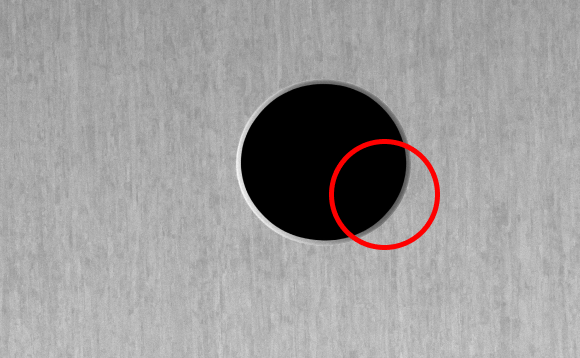

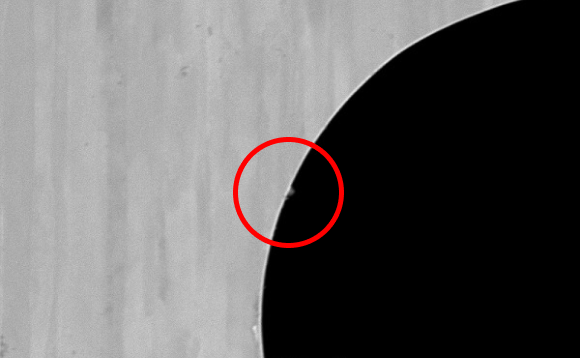

Elimination of slight dirt adhering to Mo apertures by cleaning

Before cleaning (1)

After cleaning (1)

Before cleaning (2)

After cleaning (2)

Features of precision and special cleaning at Daiwa Techno Systems

- Daiwa has proprietary cleaning technology.

- After washing, a 100% inspection is performed using a microscope.

- Also capable of handling cleaning of minute parts of several millimeters and thin metal foil of 0.01 mm thickness.

At Daiwa, we perform precision cleaning of aperture plates, which are parts used to narrow electron beams.

Aperture plates manufactured with a variety of machining methods may appear visibly clean, but when examined at high magnification, they are usually found to be dirty due to the presence of organic substances or foreign matter.

At Daiwa, we have an extensive track record ranging such cleaning processes to inspection and shipping. We specialize in small parts from those as small as your fingertip to those that can fit in the palm of your hand.