Welding, assembly technology, and heat treatment for electron source, X-ray source filament machining

Tungsten filaments are widely used as electron sources in electron microscopes and as ion or X-ray sources in analytical equipment.

Daiwa’s tungsten filaments are made by concentrating technology and know-how from material selection to fine wire machining, spot welding, precision assembly, and vacuum heat treatment.

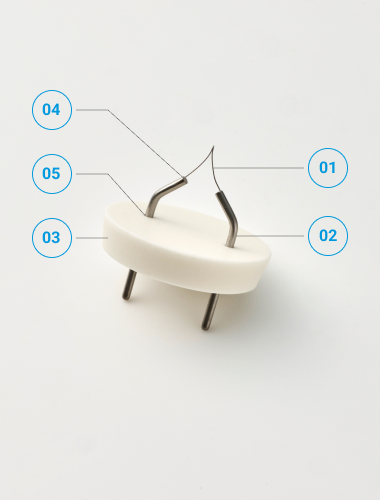

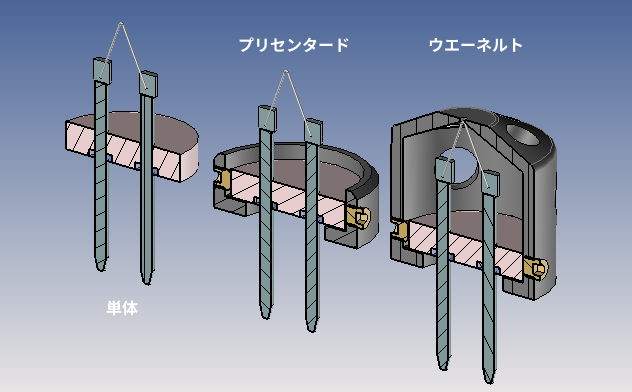

Thermal-electron gun structure and manufacturing features

Wide variety of tip shapes (sharp type, semi-pointed type, pointed type)

- KovarIron-nickel alloy that is widely used in vacuum parts because it can be sealed with glass

- Molybdenum (Mo)Non-magnetic, high melting point metal, and high-grade material for electron optics. Bonding with ceramic is achieved by metallization and brazing.

- Tantalum (Ta)Like MO, tantalum is a non-magnetic, high melting point metal, and is a high-grade material for electron optics.

- BrazingMetallization is performed on the ceramic surface, and bonding and sealing are performed by brazing.

- Glass sealSecures the ceramic and pins using glass (Kovar glass) with adjusted thermal expansion ratio. Glass seal offers benefits in terms of cost and delivery time over brazing, but there are conditions attached to airtightness and operating temperature.

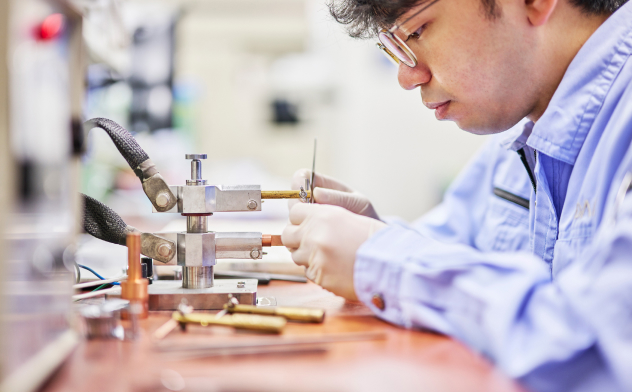

Precision assembly by spot welding

Daiwa performs spot welding for filament production. In this process, assembly work is carried out with high-accuracy geometric tolerances such as coherency and parallelism, which are important for filament performance, and dimensional tolerances for height dimensions, etc.

Our spot welder uses a dedicated filament welder we developed in-house, and comes with various jigs and tools for precision assembly.

Centering adjustment

After mounting the spot-welded filament in a metal holder, centering adjustment is performed.

Because the filament must be centered with respect to the Wehnelt in order to obtain a sufficiently bright electron beam, centering the filament tip is an important process required to achieve desired performance.

Daiwa has developed and employs its own dedicated centering jig, and performs a 100% inspection with a projector prior to product shipping.

With pre-centered filaments, there is no need for the user to perform centering when replacing the filament. With filaments with integrated Wehnelt electrode, there is no need for the user to perform Wehnelt cleaning.

Daiwa also handles batch assembly and manufacture of electronic gun units including extracting electrodes, etc.

Filament heat treatment

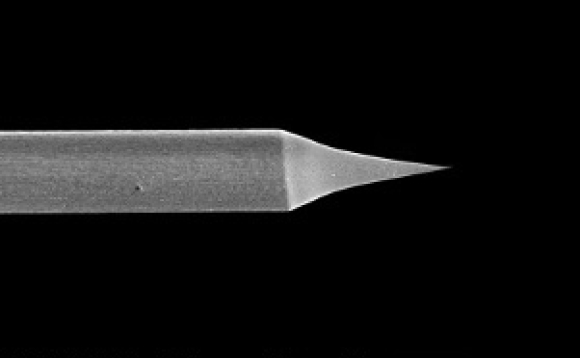

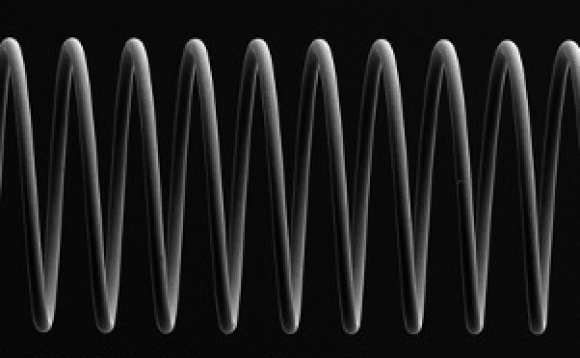

Daiwa also possesses various technologies including tip machining for sharpening tungsten tips to a needle point, and precision machining technology for coil filaments.