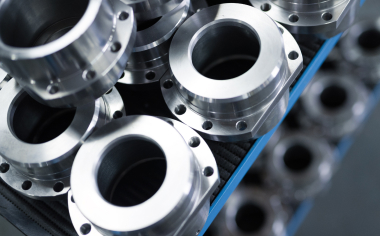

Surface treatment and heat treatment

We provide all kinds of surface treatment such as plating, heat treatment, and deposition after parts have been machined.

Daiwa saves you the trouble of outsourcing parts to a plating company after they’ve been machined, and delivers them as specified in the completion drawings.

Daiwa processing capabilities

Plating

| Electroless nickel plating | We also handle complex shapes with uniform film thickness. |

| Thick electroless nickel plating | Plating can be applied with thickness of 100 μm. |

| Black electroless nickel | Available in bright and matte plating. |

| Tinning | Matte plating for industrial applications |

| Silver plating | Matte plating for industrial applications |

| Gold plating | Hard plating for industrial applications |

| Chrome plating | Hard chrome plating |

| Other | Various other plating types |

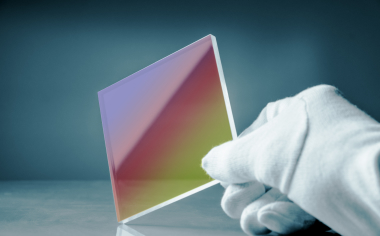

Thin film processing

| Sputtering | Au, Pt, C, Al, Cr, Pd, Y, various alloys |

| Vapor deposition | Au, Pt, C, etc. |

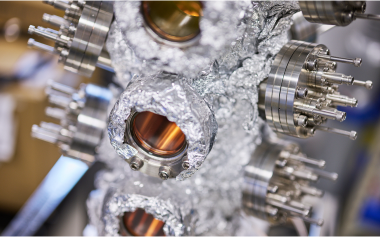

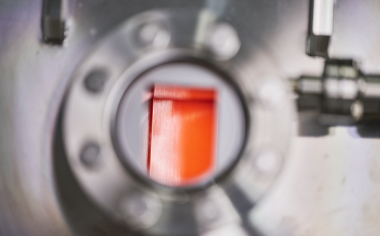

Heat treatment

| Vacuum heat treatment | Various hardening treatments (age hardening, precipitation hardening, quenching) |

| Demagnetization annealing | Demagnetization treatment for SUS316, etc. |

| Vacuum degassing treatment | Degassing treatment of vacuum parts |